Auto Ordinance 1911 A-1

Auto Ordnance WWII Model

I get the urge to do a 1911 “semi-build” every so often. I detest angled serrations, etc. and wanted the base gun as GI as possible. The finished product was to be reminiscent of the old “hardball guns” of the ’70’s; maybe high-profile fixed sights, basic accuracy and reliability work, and not much else. After pricing various guns, and reading of significant QC improvements by Auto Ordnance since “the Kahr change” I decided to add them to the list of possible base guns for the project. The fact A/O guns are American made was a substantial consideration. The fact that they are one of the few 1911 makers who, by their own account, work off pre-war blueprints was another significant factor. I wanted a gun that I would take pure-GI parts scavenged from gunshow tables- including barrels & firing pins.

Prior to Auto Ordnance being acquired by Kahr in 1999, A/O’s 1911’s garnered a checkered reputation. It was well deserved. I had owned one of the early guns, and worked on several more that were owned by law enforcement acquaintances. The apparitions of these problem guns haunted me. Then I found a local dealer with a new “WWII” model, which had seen some rough handling by prospective customers. This particular dealer knows me well and has no problem with me tearing down a prospective purchase.

The finish bore a few handling marks and the barrel was nothing to write home about, with “chatter marks” plainly visible in the rifling ahead of the chamber. The thumb safety was all but inoperable, requiring two hands to get it into the “safe” position. The extractor wobbled around like a loose tooth. The gun was ultimately purchased for a fraction of its retail price and I went to work on it shortly thereafter.

The holes and ports in the frame were in-spec and crisply done, and the rails on both parts looked real good. In fact, I’d have to say that the top of the frame and underside of the slide were actually finished better than the Springfield MilSpec I rebuilt, the year before.

Since I knew the factory thumb safety was suspect, I found an old GI safety in the parts bin and swapped it out. A little careful fitting produced the proper “snick” in both directions. I slapped the gun back together and loaded the magazine with Wolf hardball, and started to hand-cycle the gun. It choked on the 3rd round. I cleared it and started again, and it tossed out all but the last round. I reloaded the mag and repeated, only to be rewarded with a fail-to-eject every time. This was not looking very promising.

With the gun cleared and locked open, I wiggled the ejector. Another ‘loose tooth’, just like the extractor. Further inspection revealed that the front stud of the ejector had broken off flush with the frame- stuff like this is why I maintain that MIM has no place in a carry gun. This gun would not have fired a full magazine; it simply couldn’t have. No matter how good you get the frames and slide, the design requires and properly tempered and tuned extractor, and a solidly-mounted ejector to kick the empties out. It’d have been kinda nice if the thumb safety had worked, too.

A detail strip revealed lots of other stuff, too. The barrel had chatter marks in the rifling, the hammer & sear pins were undersize, the grip screws/ bushings were soft- overall cheapness of the small parts was as plain as the nose on your face.

This pistol convinced me that all this talk about ‘greatly improved guns’ from Auto Ordnance is fertilizer. The envelope containing the fired case is dated in May of ’05, and the QC on this gun was as bad as anything that ever left West Hurley. We’re right back to where we were, before the Kahr buy-out. Buy an A/O if you’re a builder, or as a shooter if you have exceptionally good luck. You just might get a perfect one- but if your good fortune is that predictable, maybe you should buy lottery tickets instead!

Brownell’s got yet another order from me, and I got busy scrounging GI hammer & sear pins, etc. When the box from Brownell’s arrived, I installed an Ed Brown extended ejector and extractor. The gun had been in my possession for two weeks, and hadn’t fired a round of ammunition yet. So I was anxious to shoot it, despite the 33-degree weather and 30+ gusts from the west.

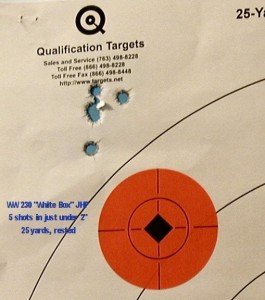

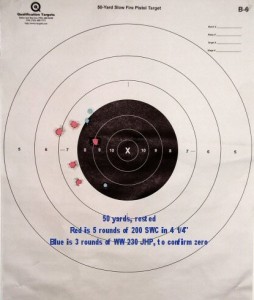

I tacked a 50 yard bull up, and backed the truck about 50 yards away; I paced it off later and found it to be about 55. Resting the gun over the open door, I fired a couple of magazines of Wolf hardball, using a 6 O’clock hold. I figured I’d at least get enough of ’em on the paper to get an idea of where the gun was shooting… the results turned out better than I expected, despite the rough barrel and GI sights:

There were no malfunctions of any kind.

I contacted Auto Ordnance and told them what I had found. To their credit, they shipped me anything I asked for in replacement parts. They would have been just as happy to work on the gun themselves, but I didn’t want to ship it cross-country and they fully understood that this was a ‘project gun’ – so they were generous with replacements. While I was waiting for the new barrel, I loaded a bunch of 200 grain SWC reloads and started stockpiling factory loads.

I shot the gun whenever I got a chance, and it continued to run without any problems. The only remaining ‘function gremlin’ was that it balked at ejecting live rounds of Wolf hardball, when clearing the gun. Replacing the undersized factory firing pin stop with Brown’s ‘max dimension’ replacement cured that. A friend provided a genuine GI trigger the short, checkered face – far and away my favorite for carry guns. Some Navridex ‘double diamond’ grips added another touch of class- and these welcome additions made the gripping gun feel like the handshake of an old friend.

The replacement barrel from Auto Ordnance eventually arrived, and it was a good-looking a GI-style barrel with an exceptionally well-executed wadcutter throat. I installed it and kept burning ammo. Accuracy was OK for a GI gun, but nothing to write home about- 2.5 to 4 inches at 25 yards. Most of the inaccuracy was due to horizontal stringing.

This gun had now run flawlessly for 800 rounds since the rebuild, excepting 2 malfs with rounds that were clearly out of spec. One of those was a bad reload and the other was a round of Wolf 230 hardball with an .007” undersize rim. Wolf is OK ammo, and has proven good for at least 5-6 inches at 50 yards from my more accurate .45’s-which in my estimation is sufficient for anything short of the National Matches.

I figured the accuracy issue was just the combination of a mediocre barrel & GI bushing, so I ordered a MGW .580 bushing and installed it. Accuracy immediately got worse, again with horizontal stringing. I examined the bottom lugs. Wear patterns made it apparent that they were barely contacting the slide stop-which was a full-dimension replacement with a .200 crosspin. I yanked the link out and measured it, thinking it would be a standard .278 GI link. Wrong-O; it was .283 inches. Rooting around in the parts bin, I finally located a .280 link, installed it, and trudged off to the range, not expecting much. In the interests of removing operator error, all shooting was done over the hood of my pickup, using the range bag as a rest.

Groups with the GI bushing ’rounded up’ immediately, hovering at 2 ½” or so with all ammo- we were onto something here. I plugged in the MGW bushing, which provides for about .003 clearance using this barrel. Things got better still:

It was time for some 50 yard testing. My informal target load consists of a 200 SWC, over 5.0 of Winchester 231 in mongrel brass. It has always been a good shooter. Three rounds of Winchester “white box” 230 JHP also shot mostly into the same group. This gun is shooting as almost well as my late-lamented ’91-A1 Commander, and my old AMU-built Ithaca.

In addition to shooting good, it is boringly reliable. 500 rounds of the SWC reload disappeared, as did another 500 of Wolf hardball. 100 rounds of Remington 230 grain UMC/JHP’s convinced me that it was neither as slick nor accurate as Winchester version of this load, in this gun- but it fed every one of them without a hitch. I staked in a King-Tappan front sight and added a plain black Colt 80 Series rear sight. The round count continued past 2000- still no malfunctions. So in the end, the Auto Ordnance was just what I wanted it to be- the basis for a super-reliable, good-shooting American GI-blueprint gun. It wasn’t perfect in the beginning, but it sure responded well to some TLC and a little bench time. I’m happy with the results.

Tom Pelle

Sarge,

I’m seriously considering adding one of these Auto Ordnance WWII model pistols to my arsenal. Like you, I prefer the simple traditional look sans billboard rollmarks, and it appears to me that the AO 1911 has exactly the appearance that I am looking for, as well as correct-appearing detail parts. (The Cimarron 1911 is a close second, but is an Armscor pistol from Philippines. And its thumb safety would have to be replaced or re-worked to get the “correct” look.)

Your pistol was built in ’05, it seems. With 7 years of more experience and refinement, do you think Kahr has improved any?

Sarge

Thanks for your comment, Tom. I’m afraid my most recent experience with the Kahr A/O’s is the pistol featured in this article. When in doubt about any current offering, I google “______ range report” and see what comes up. You’ll spend some time digging through irrelevant data, but if you’re persistent you usually find recent, relevant user reports.

The Cimarron 1911 is a good looking pistol and I personally wouldn’t let the ‘Made in the Philippines’ stamp keep me from buying one. I really wish Rock Island would offer a USGI Blueprint 1911A1 w/o that ridiculous billboard, which just gets bigger and gaudier all the time.

Tom Pelle

Sarge,

I finally did buy the new Auto Ordnance 1911 – model PKZ-SE – the WWII edition. So far I am very happy with it. Fit and finish is very good – way better than my Colt 1991-A1. Shake this pistol and there’s no rattle. I bought four new Metalform flat-follower magazines to use with it, and ran at least two mags of WWB 230 grain JRN through it with no issies. I did try some cast bullet reloads, 230 grain round nose, and they absolutely would not chamber. The slide would stop about 1/4″ to 1/8″ from going into battery, and I would have to push the front of the slide against a wooden bench at the range and smack the rear of the grip frame to free it up. Accuracy was great! If I did my part I could regularly hit tin cans at 20 or so yards, and sometimes even hit the can again while it was still rolling. Because the other ranges were busy with a hunter safety class I couldn’t shoot paper for groups, but I’ll be getting back to you.

I did use a file on the thumb safety to adjust the curve that the plunger works in to make the safety a little more positive, and I notice a little fore-and-aft play between the bushing and the front of the slide – maybe a very tight 0.006″, which is as small as my feeler guages go.

Trigger pull is about 8-1/2 pounds though, so a C&S flat spring may be in its future.

Overall, I think I got a good one!

Tom Pelle

I should have said “Ran at least two magazines full from each of the four magazines”.

RICHARD RUSSELL

I just bought a 1911 -A1 45 ACP MFG BY AUTO ORDINACE WITHOUT ANY

PAPERWORK COULD YOU PLEASE EMAIL ME A DIAGRAM AND ANY

INFO ON CLEANING IF POSSIBLE?

THANX

R RUSSELL

Sarge

Richard,

IF you contact Auto Ordnance at they will, in all likelihood, send you a schematic and parts list. YouTube is loaded with cleaning and disassembly videos, if you care to look for them.

Tom Murray Sr

I just got a AO 1911A1 and cannot find a way to determine date of manufacture. Is there a website or link that I could use. Thank you, Tom

Sarge

My suggestion is to just call Auto Ordnance.